ExcerptThis article discusses the process of generating material confirmations in iDempiere ERP. It explains the steps involved in creating a receipt confirmation for materials and how the system automatically updates the receipt data once the confirmation is completed. By using iDempiere’s material confirmation feature, businesses can ensure the accuracy of their inventory and streamline their…

iDempiere ERP is an open-source enterprise resource planning (ERP) system that offers a wide range of functionalities for managing business processes. One of the core modules of iDempiere ERP is the Material Receipt and Confirm module, which is used for managing the receipt of goods and confirming their delivery.

The Material Receipt and Confirm module allows organizations to efficiently manage the receipt of goods, including raw materials, finished products, and supplies. It provides a streamlined process for receiving goods, tracking inventory levels, and confirming delivery, which helps to ensure that the right products are available at the right time and in the right quantities.

When a purchase order is created in iDempiere ERP, the Material Receipt and Confirm module allows users to create a corresponding receipt record for each item in the order. This receipt record contains information such as the quantity of the item received, the date of receipt, and the supplier information. Once the goods have been received, users can then confirm the receipt, which updates the inventory levels in the system.

The Material Receipt and Confirm module also allows users to manage partial receipts, which can be useful when only a portion of the order has been received. For example, if an order for 100 units is placed, but only 50 units are received, users can create a partial receipt for the 50 units and update the remaining 50 units as back-ordered. This helps to ensure that inventory levels are accurately reflected in the system and that future orders can be placed accordingly.

In addition to managing the receipt of goods, the Material Receipt and Confirm module also provides functionality for managing returns and rejections. If a shipment is received and found to be defective or incorrect, users can create a return record to initiate the process of returning the goods to the supplier. Similarly, if goods are received and found to be unsatisfactory, users can create a rejection record to initiate the process of rejecting the goods and forming a replacement order.

Overall, the Material Receipt and Confirm module in iDempiere ERP is an essential tool for managing the receipt of goods and confirming their delivery. It provides a streamlined process for receiving goods, tracking inventory levels, and managing returns and rejections. By using this module, organizations can improve their supply chain management processes and ensure that the right products are available at the right time and in the right quantities.

How to receive and return non-inventory items?

This is a topic worth exploring. In iDempiere ERP, the process of receiving and returning also applies to non-inventory items.

For non-inventory items, such as services or other expenses, the receiving process may involve more documents or agreements. The Material Receipt and Confirm module in iDempiere ERP provides a function to associate relevant documents or agreements with specific orders or items. After the receipt is completed, the related documents or agreements will be archived and can be queried and retrieved through the document management system in iDempiere ERP.

If a return or refund is needed, the processing method for non-inventory items is different from that of inventory items. In iDempiere ERP, a Credit Memo can be used to handle returns or refunds. When a return or refund is needed, a Credit Memo can be created to associate the relevant order or item with the amount. Then, the Credit Memo can be sent to the supplier or customer for the return or refund process. In iDempiere ERP, the progress of returns or refunds can be tracked by querying the status of the Credit Memo.

In summary, the process of receiving and returning non-inventory items can be managed through the Material Receipt and Confirm module in iDempiere ERP. The module provides a powerful system that can associate relevant documents or agreements with orders or items and handle returns or refunds through Credit Memo. This can help organizations better manage the process of receiving and returning non-inventory items and improve supply chain management efficiency.

The workflow of Material receipt confirmation

The Material Receipt Confirm process begins with creating a purchase order for the items that need to be received. Once the order is created, the items are shipped from the supplier to the receiving location. The receiving personnel then physically receive the items and verify that the quantity and quality of the items received match the information on the purchase order.

After verifying the items received, the receiving personnel then log into iDempiere ERP and create a receipt for the items in the system. The receiver can manually or automatically generate a confirmation receipt after inputting the received quantity, which will be thoroughly inspected by the IQC or other department personnel, and record the confirmed quantity and scrapped quantity. After completion, the data will be automatically updated to the receipt. They can also attach any relevant documents or agreements related to the receipt.

Once the receipt is created, the system will automatically update the inventory levels and the purchase order status in real time. If there are any discrepancies or damages, the system will also create an alert or notification for the relevant personnel to take corrective action.

The Material Receipt Confirm process is not limited to inventory items only. Non-inventory items, such as services or expenses, can also be managed through the Material Receipt Confirm module in iDempiere ERP. For non-inventory items, the relevant documents or agreements can be attached to the receipt and a Credit Memo can be used to handle returns or refunds, as I explained in my previous response.

In conclusion, the Material Receipt Confirm process in iDempiere ERP streamlines the process of receiving and managing items, both inventory and non-inventory, by automating inventory updates, providing alerts for discrepancies or damages, and associating relevant documents or agreements with the receipts.

The differences between the PickQAConfirm and ShipReceiptConfirm type in iDempiere ERP

PickQAConfirm is a type of confirmation used to verify the picking and quality assurance of items prior to shipment. This confirm type is used when items are being prepared for shipment from a warehouse or distribution center. In this process, the system generates a pick list based on the sales order or other shipping document. The pick list identifies the specific items and quantities that need to be picked and prepared for shipment. Once the items are picked, they are then sent to the quality assurance area for inspection. The quality assurance personnel will check the items to ensure they meet the required quality standards. If any issues are found, the items may need to be reworked or replaced before they can be shipped. Once the quality check is completed, the PickQAConfirm is created to confirm that the items are ready for shipment.

On the other hand, ShipReceiptConfirm is a type of confirmation used to verify the receipt of items by the customer. This confirm type is used when items are delivered to the customer’s location. In this process, the items are shipped from the warehouse or distribution center to the customer’s location. Once the items arrive at the customer’s location, the customer verifies the items received and confirms the shipment. This confirmation can be done through the ShipReceiptConfirm in iDempiere ERP. The ShipReceiptConfirm verifies that the items were received in good condition and that the quantity and quality of the items received match the information on the shipping documents. This confirmation triggers the final steps in the order fulfillment process, such as invoicing and payment processing.

In summary, the PickQAConfirm and ShipReceiptConfirm confirm types serve different purposes in the order fulfillment process. PickQAConfirm is used to verify the picking and quality assurance of items prior to shipment, while ShipReceiptConfirm is used to verify the receipt of items by the customer. Both confirm types are important for ensuring the accuracy and quality of the items being shipped and received and are key components of the overall order fulfillment process in iDempiere ERP.

How to calculate the actual quantity received?

| Confirmation Type | Calculation of Material Receipt Movement Quantity |

| PickQAConfirm | Movement Quantity = Confirmed Quantity (confirm) Picked Quantity = Confirmed Quantity (confirm) Scrapped Quantity = Scrapped Quantity (confirm) |

| ShipReceiptConfirm (In Material Receipt) | Movement Quantity = Confirmed Quantity + Scrapped Quantity (confirm) |

For example

Entered Quantity = 100

Confirmed Quantity = 70

Scrapped Quantity = 30

| Confirmation Type | Calculation of Material Receipt Movement Quantity |

| PickQAConfirm | Movement Quantity = 70 Picked Quantity = 70 Scrapped Quantity = 30 |

| ShipReceiptConfirm (In Material Receipt) | Movement Quantity = 100 Scrapped Quantity = 30 |

How to generate material confirmation manually and automatically?

Manually

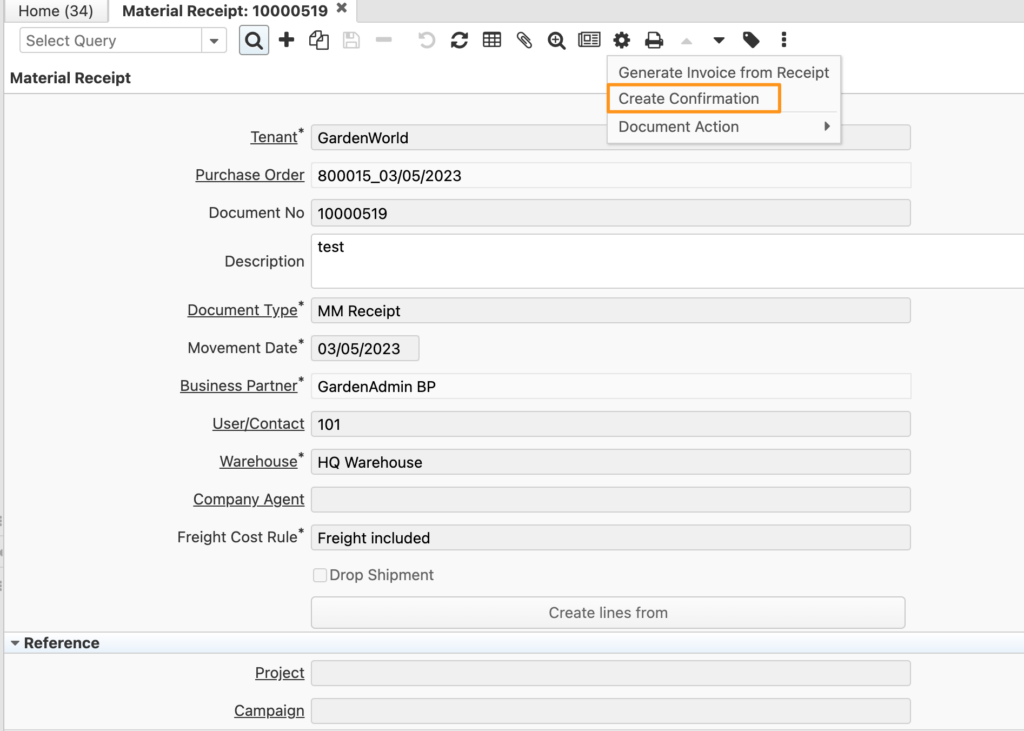

Click on the “Create Confirmation” process icon in the toolbar.

Automatically

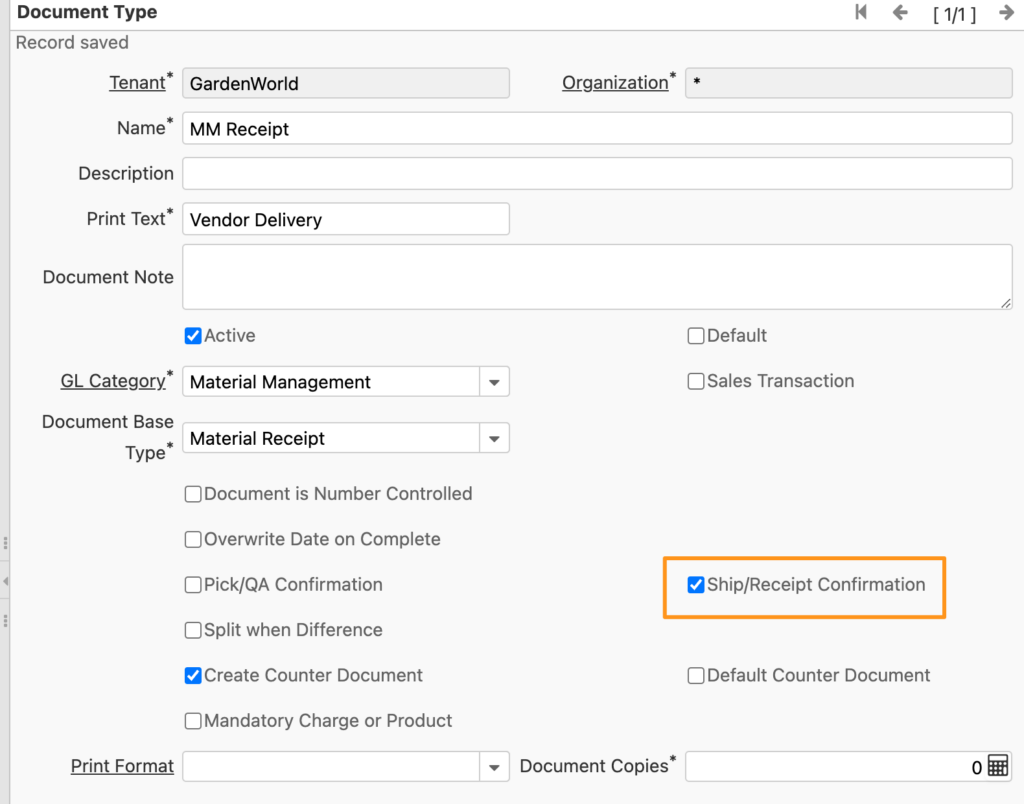

In the material receipt document type, ensure that “Ship/Receipt Confirmation” is selected. When the document action “Prepare” or “Complete” is clicked, the system will automatically generate a confirmation.

Conclusion

In conclusion, material confirmation plays a crucial role in ensuring the accuracy of inventory records and optimizing warehouse management processes. By confirming the receipt of materials, companies can verify the quantity and quality of the received goods, update inventory records, and identify any discrepancies or issues that need to be addressed. With the help of advanced ERP systems, companies can automate the material confirmation process and reduce the risk of errors or delays caused by manual data entry. By implementing best practices for material confirmation, companies can improve their inventory accuracy, reduce costs, and enhance their overall operational efficiency.

[…] Streamlining Supply Chain Management with iDempiere ERP’s Material Receipt and Confirmation Mo… ConfirmationMaterial Receipt By Insider Editor 0 Comments […]